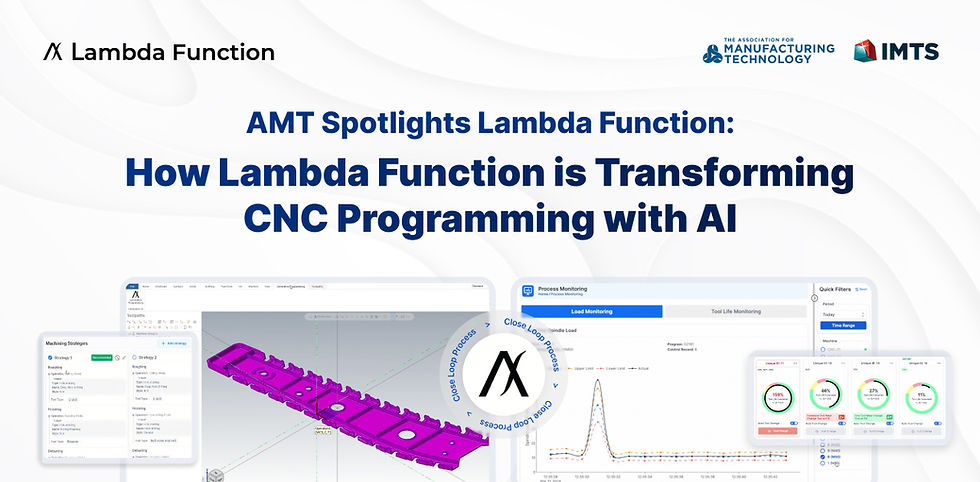

AMT Spotlights Lambda Function: How Lambda Function is Transforming CNC Programming with AI

- Tanmay Aggarwal

- Sep 10, 2025

- 3 min read

Updated: Sep 12, 2025

CNC programming is at an inflection point. Rising complexity, skill shortages, and the need for continuous improvement are accelerating demand for intelligent automation. The convergence of AI and CAM is no longer optional — it is becoming a competitive necessity.

Recognizing this, AMT recently featured Lambda Function’s role in reimagining CNC programming with AI in their article “How AI Is Reshaping CNC Programming for Faster, Smarter Cuts.” The write-up highlighted how AI is not just a futuristic concept, but a present-day solution that is already reducing programming time, extending tool life, and delivering shop-floor insights.

For us, this recognition reinforces our belief that the future of CNC programming lies in augmenting, not replacing teams — creating adaptive systems that learn from every tool, every cut, and every decision to drive efficiency across the shop floor.

Why AI Belongs in CNC Programming

CNC programming has long relied on the experience and intuition of skilled machinists, often supported by repetitive trial-and-error. While this expertise is critical, it’s difficult to capture, scale, and share across teams. At the same time, manufacturers face growing pressure to:

Reduce setup times and lead times

Extend tool life while maintaining part quality

Preserve and apply best practices consistently across projects

AI addresses these challenges by analyzing part geometry, material behavior, and machinist input to generate intelligent recommendations. The result: programming that once took days can be completed in hours, with greater accuracy and continuous improvement built in.

Lambda Function’s Approach

At Lambda Function, we design AI to augment CNC teams, not replace them. Our CNC programming module combines machine intelligence with human expertise, delivering data-driven insights that evolve with every project.

Here’s what it enables:

Machining Strategy Recommendations – Suggests the most effective strategies based on part features and geometry.

Cutting Tools & Parameters – Uses material removal physics and machine learning to recommend optimal tools, speeds, feeds, and depth of cut.

Toolpath Guidance – Generates toolpath options aligned with strategies, materials, and tool choices for reliable and consistent programming.

Collaboration & Knowledge Retention – Supports single or multi-user collaboration, while securely capturing learnings in the cloud to accelerate future projects.

The outcome: a more adaptive CAM workflow that reduces programming time, improves consistency, and ensures expertise becomes a lasting asset for the entire team.

Beyond Toolpaths: Smarter Decisions, Longer Tool Life

Lambda’s technology goes beyond programming. We use spindle load data and energy-based models to predict tool life more accurately. This not only helps machinists prevent tool failure but also ensures tools are used to their maximum safe potential, reducing waste and cost.

And because the system learns from each decision and outcome, it becomes a continuous improvement engine — one that scales across teams, shops, and even entire enterprises.

The Bigger Picture: AI as a Partner in Manufacturing

At Lambda Function, we often say that AI in CAM must earn the trust of shop floor experts before it can transform their workflow and we couldn’t agree more. That’s why we focus on flexibility, providing multiple strategies, so the processes stay in control.

When trust builds, adoption follows. With adoption comes confidence that leads to a shop floor where programming is faster, cuts are more precise, and machinists have the right digital partner to amplify their skills.

Looking Ahead to AMT’s Biggest Event: IMTS 2026

Lambda Function will be at IMTS 2026 in Chicago, joining hundreds of innovators shaping the future of manufacturing. We’re excited to showcase how AI-assisted CNC programming can help manufacturers cut smarter, boost efficiency, and stay competitive in a rapidly changing industry.

Comments